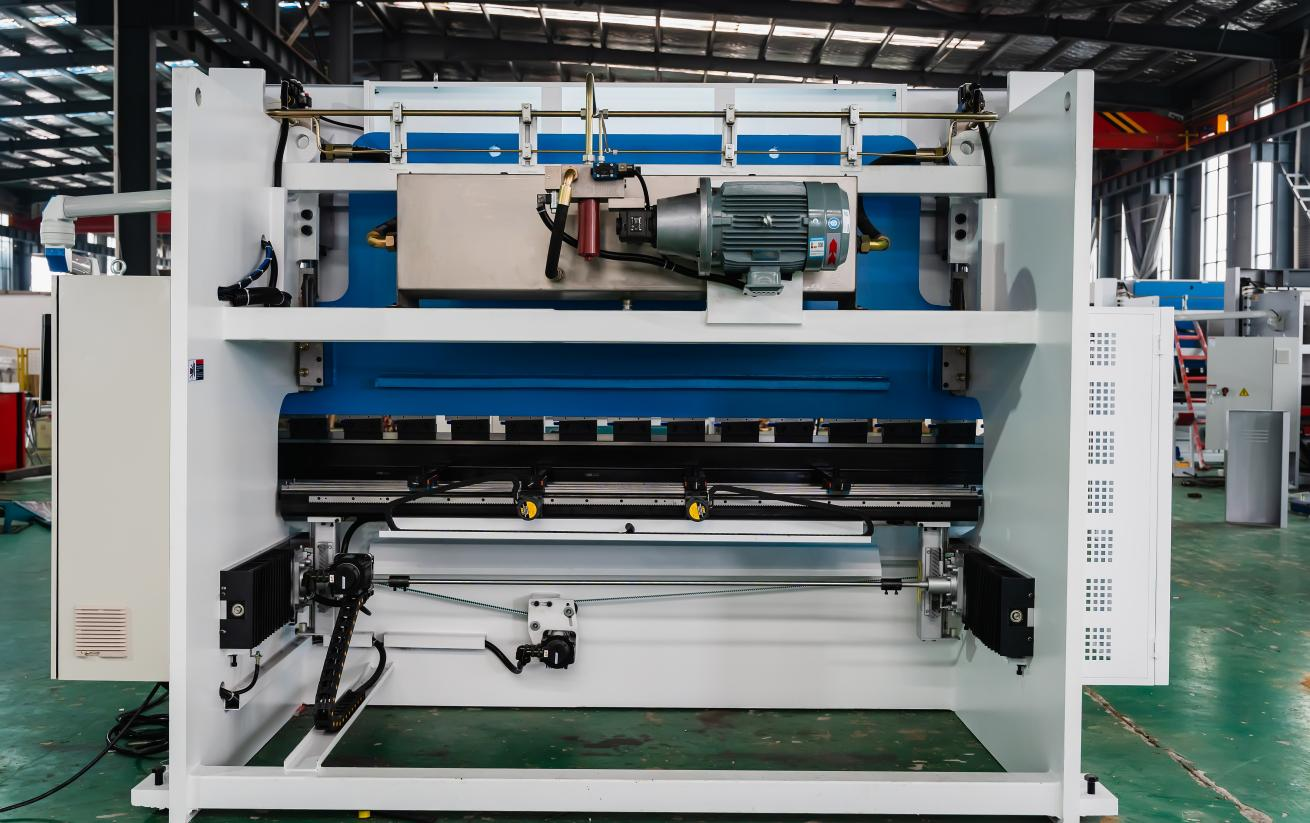

进口系统电液伺服数控折弯机/Imported system electro-hydraulic servo CNC bending machine

产品介绍/Product presentation

1.焊接钢结构,通过正火和高频振动消除应力,保证机床的整体精度,具有优异的刚度、抗扭曲、抗倾斜能力。

2.两侧主缸属于电液数控折弯机数控轴,其中Y1、Y2轴,同步兼容德国进口液压伺服阀和德国海德汉光栅闭环控制,重复滑块精度和平行精度可达+/-0.01mm。

3.工作台(V轴)液压凸度自动补偿系统,数控系统自动调整补偿次数。(可选机械补偿表结构)。

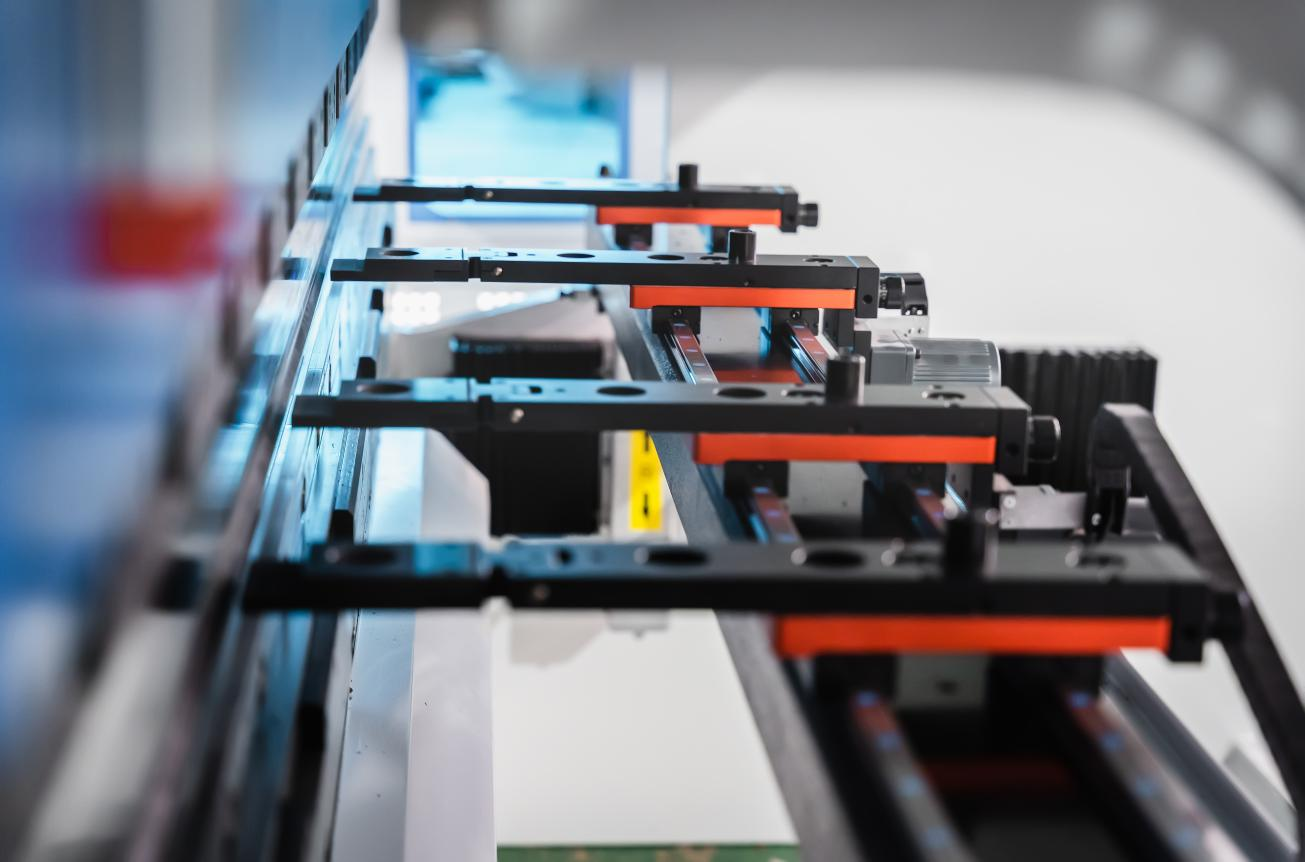

4.后规(前后位置)是数控折弯机中的X轴,由伺服电机、数控系统驱动,通过精密滚珠丝杠、直线导轨传动(用户可以扩展R轴或R1轴、R2轴、Z1轴、Z2轴等)。

5.机器两端都装有安全护栏。

1. Welded steel structure, through normalizing and high-frequency vibration to eliminate stress, to ensure the overall accuracy of the machine, with excellent stiffness, anti-distortion, anti-tilt ability.

2. The master cylinder on both sides belongs to the CNC axis of the electrohydraulic CNC bending machine, among which the Y1 and Y2 axes are synchronously compatible with the hydraulic servo valve imported from Germany and the closed-loop control of the Heidehan grating, and the accuracy of the repetitive slider and parallel accuracy can reach +/-0.01mm.

3. Workbench (V-axis) hydraulic crown automatic compensation system, CNC system automatically adjust the compensation number. (Optional mechanical compensation table structure).

4. The rear gauge (front and rear position) is the X axis in the CNC bending machine, driven by the servo motor and CNC system, driven by the precision ball screw and linear guide rail (users can expand the R axis or R1 axis, R2 axis, Z1 axis, Z2 axis, etc.).

5. Safety guardrails are installed at both ends of the machine.