扭轴伺服数控折/Torsion axis servo CNC bending machine

产品介绍/Product presentation

1.采用全钢整体焊接结构,通过正火及高频振动消除内应力,保证机床的整体精度,有极佳的刚度,有极好的抗扭曲、抗倾斜能力。加厚的工作台板、加厚的滑块,使整机具有很高的刚性,且整机机架焊接后整体一次性加工,因此折弯时滑块、工作台变形极小,工件具有极好的直线度和角度一致性。

2、滑块同步机构采用扭轴同步,机械档块机构,稳定可靠。

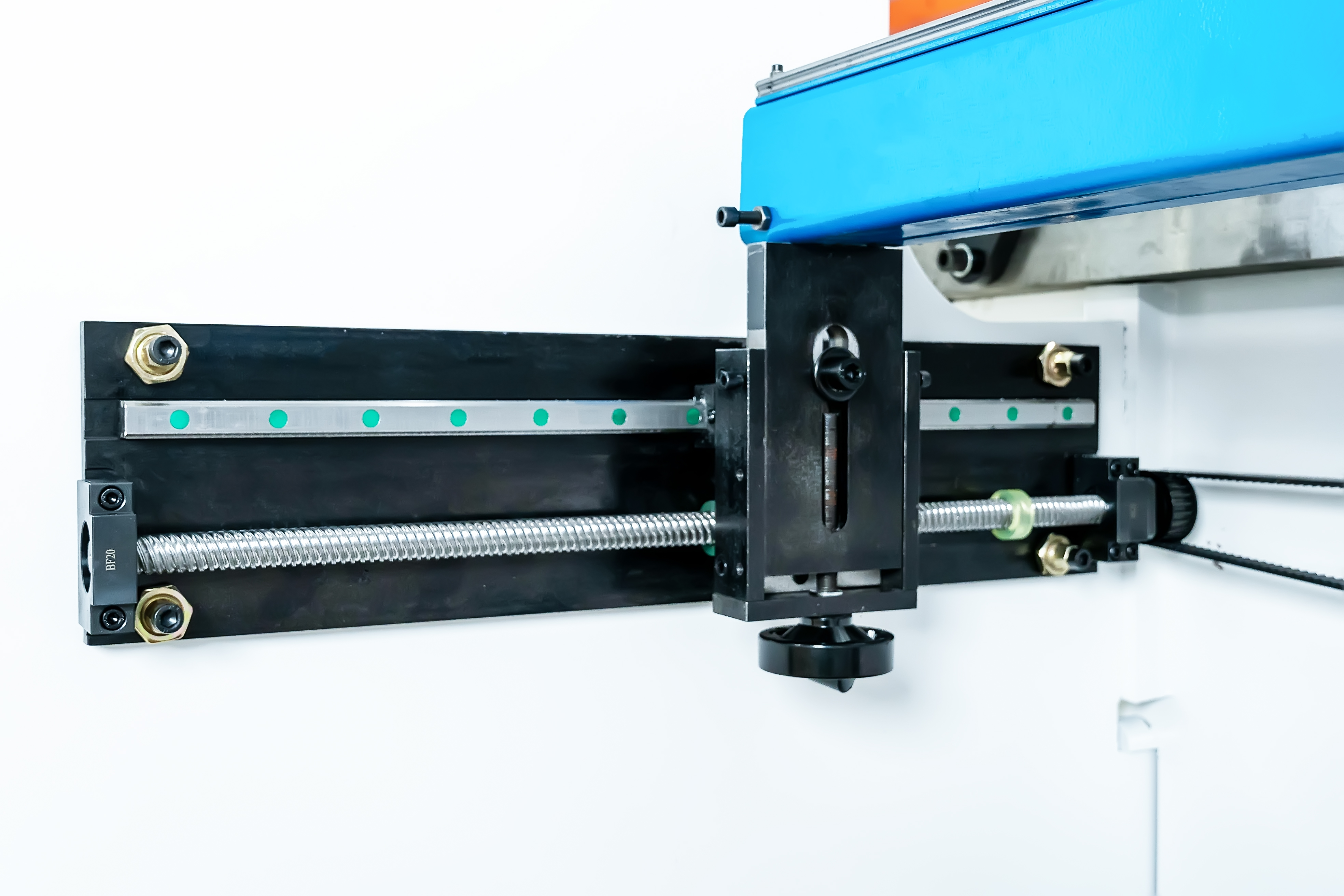

3、后挡料距离、滑块行程调整均由伺服电机驱动,数控系统控制,后挡料采用精密滚珠丝杆、直线导轨,同步轮同步带传动,运行快速、定位数据精密。数控系统选用两轴伺服控制技术,可设定并保存一个百个折弯程序,每个程序下设多个工步编程。

4.前托料臂横向移动采用精密直线导轨,可随意控制托料臂之间的间距,托料臂可调整水平高度,极大的提高了工件折弯的方便。

5、采用快速夹钳装夹折弯模具,并配有挠度补偿机构,以保证获得较高的折弯精度(提高精度可选配液压加凸工作台补偿或斜楔式机械工作台补偿)。

6.机床左右及后面设有安全防护栅装置、电器柜设有开门断电及前后设有紧急开关装置,带有防护罩脚踏开关,以保证工作时操作安全。

1. The whole steel welded structure is used to eliminate the internal stress through normalizing and high-frequency vibration to ensure the overall accuracy of the machine tool, with excellent stiffness and excellent anti-distortion and anti-tilt ability. The thickened workbench plate and the thickened slider make the whole machine have high rigidity, and the whole machine frame is processed once after welding, so the deformation of the slider and workbench is very small when bending, and the workpiece has excellent straightness and Angle consistency.

2, sliding block synchronization mechanism adopts torsion shaft synchronization, mechanical block mechanism, stable and reliable.

3, the rear stop distance, slide stroke adjustment are driven by servo motor, CNC system control, the rear stop using precision ball screw, linear guide, synchronous wheel synchronous belt transmission, fast operation, precise positioning data. CNC system adopts two-axis servo control technology, can set and save a hundred bending program, each program under multiple work step programming.

4. The transverse movement of the front supporting arm adopts precision linear guide rail, which can control the distance between the supporting arm at will, and the supporting arm can adjust the horizontal height, which greatly improves the convenience of workpiece bending.

5, the use of fast clamp clamping bending mold, and equipped with deflection compensation mechanism to ensure a high bending accuracy (improve the accuracy of the optional hydraulic plus convex table compensation or oblique wedge type mechanical table compensation).

6. The machine tool is equipped with a safety fence device on the left and right side and behind, the electrical cabinet is equipped with an emergency switch device before and after the door is opened and the power is off, and the foot switch with a protective cover is equipped to ensure the safe operation during work.